Pulp & Paper

PBE Expert Inc, is a leading consulting company providing innovative and practical solutions to the Pulp and Paper industries, including process engineering and optimisation, energy efficiency involving multidisciplinary resources, engineers, project managers and senior experts. Détails: CRIP-Biorefinery

PBE Expert Inc is committed to providing projects delivery on time, on budget and compliant to quality requirements.

PBE Expert Inc was involved in several projects and innovative Pulp & Paper process development & implementation, including digital technologies, data collection, access security, computer data integrity audit, and their validation in accordance with the industry 4.0.

Process, Building, Energy

PBE Expert Inc serves Pulp & Paper Industries by providing services in Process Engineering, Layout, Energy Efficiency & Warehouses, Maintenance, Calibration, Data Collection & Security, Industry 4.0, and implementation of the Quality System ISO-9001.

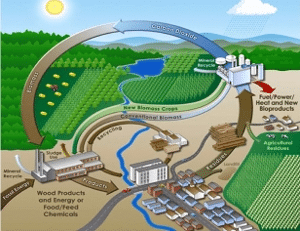

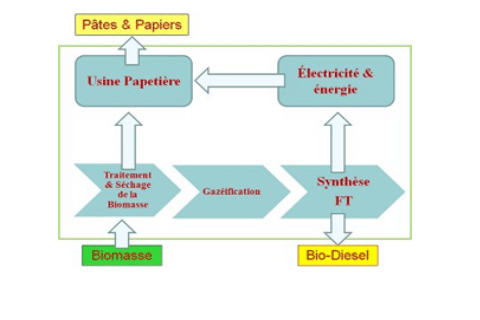

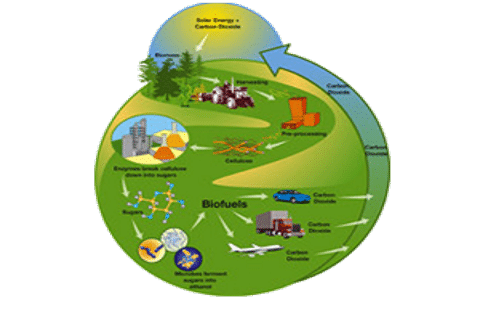

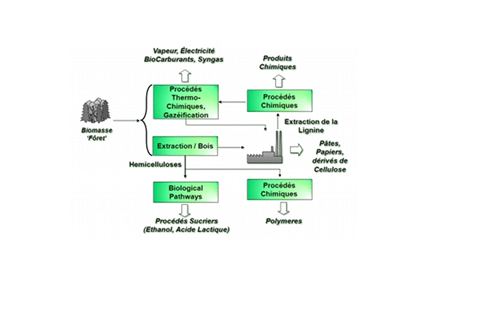

The design of the production equipment, utilities and systems according to GEP: Good Engineering Practices, including energy optimization technologies through integrated biorefinery solutions to upgrade sub-products (lignin, of 2nd & 3rd biomass generation) to valuable products and energy.

Environments issues and related process hazards shall to be controlled and mitigated to acceptable levels by means of innovative preventive technologies and HAZOP, FMEA risk management assessment. Therefore, the implementation of the corrective and preventive measures, the management of non-compliant products, systems of registration and traceability as well as the application of the procedures and audits are guarantees of quality.

- Pulp & Paper facilities design

- Integrated systems & Facilities

- Process engineering

- EPCMV & Project management

- Quality assurance, maintenance & Training

- PURS: Product, Process, Plant User Requirements Specifications”, laws and regulations analysis, ISO-9001.

- Design of general “Site Master File: SMF”.

- Design of manufacturing equipment, processes, black utilities, Layout & facilities specifications.

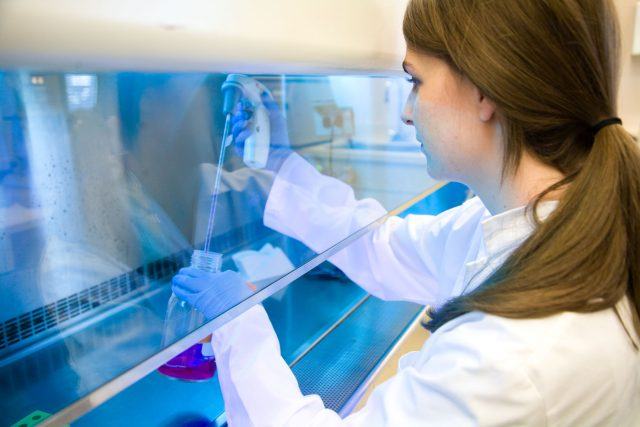

- Warehouse areas, vaults, cold rooms, and quality control Labs.

- HAZOP, Hazards Analysis & Functional Technical Program (PFT) & Facility Design Qualification (FDQ).

- Process Optimization, reduction of operating costs OPEX and CAPEX investment.

- Waste (gas, liquid & solid) neutralization treatment technologies.

- Support in certificates of authorization “CA” to comply with environmental regulation & requirements.

- Selection and implantation of manufacturing equipment and systems.

- Instruments Calibration and transition to the Industry 4.0.

- Maintenance of equipment and performances traceability.

- Functional analysis of processes, utilities and systems.

- Cross-matrix of equipment, utilities, systems, manufacturing areas, facilities.

- Analysis of flow & risks.

- HAZOP & ATEX management, impact analysis & risks mitigation.

- Design of the warehouse, “racking: Push-Back” and equipment Quality control laboratories: physico-chemical, microbiological and R&D.

- Optimization of the costs of investment CAPEX and OPEX operation.

- Energy, water & materials balances optimization.

- Energy grants applications related to 2nd & 3rd biomass generation.

- Energy efficiency, integration of renewable energies “trigeneration”.

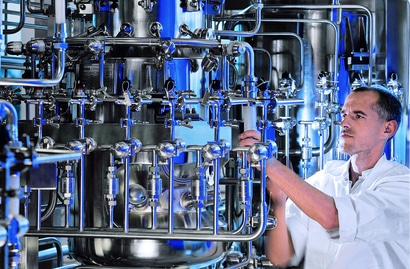

- Process Engineering, Sizing, basic and detailed design, 3D drawing and performance specifications.

- Development of PURS, URS, BOD, DDE, PFD, P&ID and “CPP“:

- Specification of materials and chemical compatibility.

- Design and Optimization of P&ID & CPP.

- Specifications of the valves, pump, fittings, filter, exchanger, evaporator, dryer.

- 3D design of processes skids, and related equipment.

- 3D design of process transfer lines (orbital welding).

- 3D design of the critical utilities, generation and distribution.

- 3D design of systems: waste treatment systems, vacuum, vent, …

- Interlock between the process equipment and facility systems & safety devices.

- HAZOP design of P&P facilities including explosive & flammable compounds risks assessment & mitigation.

- Automation, PLC, SCADA, integration, BMS, BAS, ERP, SAP, Industry 4.0.

- Engineering, validation and construction projects management.

- Suppliers and contractor’s selection.

- Works timeline, resource planning, sub-contractors coordination.

- Management, control & optimization of the project costs.

- Follow-up & technical support, review and approval of the workshop drawings.

- Plans and procedures approval of supervision and health safety (HSE).

- Equipment accessibility, reception, installation & commissioning.

- Supervision and approval of onsite contractors & suppliers drawings for execution.

- Engineering tests, “Troubleshooting“ & setting of the PLC processes.

- Management and control of work quality and equipment performances.

- Onsite works progress reports follow-up, benchmark and end of the work certificate delivery.

- Update and approval of all the facility, cleanrooms and equipment drawings and documentations “As Built“.

- Certificate of Conformity, release of payments, customer facility and documentation “hand-over”.

- Predictive maintenance, systemic, and preventive plan & program.

- Metrology, calibration program, calibration of the instruments, and traceability.

- Mapping (temperature, humidity) of warehouse & microwaves.

- Commissioning (DQ, FAT, SAT).

- Quality Assurance & In Process Control.

- Drafting of procedures: SOP.

- Manufacturing operation support and health & safety services.

- Change Control, CAPA, Failure Modes Effect Analysis : FMEA.

- Root Causes Analysis “RCA“.

- Risks management, analysis, and mitigation: HAZOP.

- Industry 4.0, IoT, collection and data integrity, CSV, ERP, SAP, LIMS.

- Training: PBE Expert Inc is a CPMT training company with agreement #0059104 & EPIC/OIQ recognition.

Regulations

GEP | AMDEC | ATEX | NFPA | HSE | SIMDUT | HAZOP