Foods

PBE Expert Inc is a leading consulting company providing innovative and practical solutions to the FOOD, DAIRY & BEVERAGE industries, involving a MAPAQ qualified Consultant to “ La mesure 2 du programme Levier”.

PBE Expert Inc is committed to providing skilled resources by delivering projects on time, on budget and compliant to HACCP, GFSI, SQF, ISO-22000 quality requirements.

PBE Expert Inc successfully accomplished several food & dairy projects (milk, cheese), beet sugar refining, oil refining & conversion into shortening, chocolate, bottling of mineral waters, juices and beverage, bakeries, chewy bars, feed mills, meat (Jerky) and food processing, energy saving and cold rooms & warehouses design.

PBE Expert Inc serves Foods, Dairy & Beverage Industries in Process Engineering, Clean In Place, Layout, energy efficiency, mapping of cold rooms & warehouses, maintenance, calibration, Quality System ISO-9001, HACCP, ISO-22000, GFSI, SQF certification. PBE Expert is a MAPAQ qualified Consultant to “ La mesure 2 du programme Levier”.

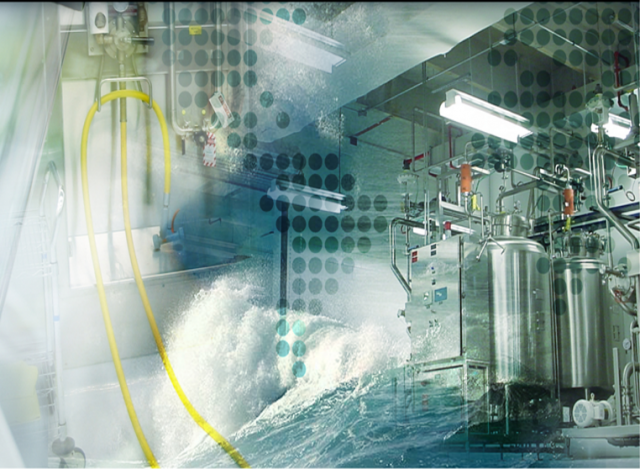

The sanitary design of the production equipment & process skids, clean utilities and systems involves the integration from the outset good engineering practices and ASME-BPE and hygienic concepts Compliance.

The food safety and hygienic manufacturing areas shall comply to related standards (ISO-14644). The Hazards Preventive Technologies (HACCP), the implementation of the corrective measures and preventive actions, the management of non-compliant products, the record and traceability systems as well as the application of the procedures and internal audits are mandatory practices to meet the foods quality and to ensure the control of the dangers that threaten the food safety.

- Foods, Dairy & Breverage facilities design

- Clean utilities & Systems

- Process engineering “ASME-BPE”

- Layouts design & Technical specifications

- EPCMV & Project management

- HACCP Compliance Audit, PAI & Training

- Quality assurance & Maintenance

- “PURS: Product, Process, Plant User Requirements Specifications”, laws and regulations analysis: HACCP, SQF, ISO-22000, GFSI, ISO-9001.

- Design of general “Site Master File: SMF”.

- Sanitary Design of skids of production, processes, Layout, cleanrooms, HVAC, design & specifications.

- Hygienic design of critical manufacturing cleanrooms.

- Specifications of cleaning & sanitisation systems and compliance procedures Clean In Place – CIP.

- Specifications of the suitable drying systems of food.

- Warehouse areas, vaults, cold rooms, and quality control Labs.

- Personnel, material & finished goods Flows & Cross-Contamination (CC) Risks assessment & mitigation.

- Critical cleanrooms, equipment & products requirements.

- Hazards Analysis of Critical Control Points: HACCP & Functional Technical Program (PFT) & Facility Design Qualification (FDQ).

- Gowning & Personnel Protective Equipment (PPE).

- Sanitary design of processes, clean utilities and sanitary systems functional analysis.

- Purity, sterility and the risk level audit assessment (ASTM2500, FMEA).

- Critical equipment & manufacturing cleanrooms Sanitisation & appropriate sterilization technologies (Autoclave).

- Equipment, utilities, systems, production rooms, infrastructure list & Cross-Matrix.

- Single Use Technology requirements and Process and CIP alternative.

- Equipment supplier’s selection and implementation.

- Risk management, impact & gap analysis and mitigation: RAPA, GAPA, ICH Q9, FMEA, ATEX.

- Warehouse, “Push-Back racking”, vaults, cold rooms and quality control Labs design.

- Hazardous chemical & biological waste gas, liquid and solid treatment technologies.

- Support in approval certification “CA“ related to environment protection (MDDELCC).

- Energy and water consumption efficiency optimization. Integration of Renewable Energies “trigeneration”.

- Sanitary Design & Process Engineering (ASME-BPE) basic and detailed, 3D drawing and performance specifications.

- Development of PURS, URS, BOD, DDE, PFD, P&ID and “CPP“:

- Specification of materials and internal finishes.

- Sanitary design, dead-legs reduction, optimization of slopes, speeds, CPP.

- Specifications of the valves (diaphragm, Block-Bleed), TC fittings, pumps, filters, exchangers.

- 3D design of processes skids and related equipment.

- 3D design of formulation, mixing and filling tanks.

- 3D design of filling machines, freeze-drying, primary and secondary packaging.

- 3D design of Clean in Place (CIP) skids, COP, sanitisation.

- 3D design of process transfer lines (orbital welding).

- 3D design of the clean utilities, production and distribution.

- 3D design of pharmaceutical systems: HVAC, FFU, autoclave, freeze-drying, vacuum, vent, …

- 3D design of protective equipment: laminar flow hood, weighing & sampling (UDAF) cabinet, LEV.

- Interlock between the process equipment and building systems & safety devices.

- Automation, PLC, SCADA, integration, BMS, BAS, ERP, SAP, Industry 4.0.

- Classified areas (A, B, C, D, ISO5-8) and (3D) architectural drawings integration.

- Layout integration of the environmental conditions and the specifications of the products: hygroscopic, electrostatic Chemical Containment OEL1-6, explosive, flammable ATEX1-4, biological containment BSL1-4.

- Development of cleanrooms URS and Critical Environmental Parameters Reviews “CEP“.

- Flow of personnel, equipment, raw material, primary & 2nd PGK materials, finished products, waste.

- Functional grouping, pressure & cleanliness cascades and classification of cleanrooms, ATEX, HR%, BSL, OEL.

- Physical (PAL, MAL, corridors) and mechanical segregations, SOP, gowning.

- Aeraulic diagrams: HVAC, FFU and laminar flow.

- Containment: RABS, isolator, “Glove-Box”, closed equipment and “Split-Valves”, LEV.

- Weighing & sampling (UDAF) cabinet.

- Design of warehouses, “Push-Back racking”, freezers -20°C, cold rooms 2-8°C.

- Raw materials & drugs, in Quarantine, Stability & Batch release (ERP).

- Vaults of controlled substances, alcohol, cannabis, THC, QPIC Services.

- Explosion proof (XP) design (NFPA, ATEX), biological containment (BSL) and chemical (OEL).

- Layout of quality control of physical & chemical, microbiological and R&D Labs

- Engineering, validation and construction projects management.

- Suppliers and contractor’s selection.

- Works timeline, resource planning, sub-contractors coordination.

- Management, control & optimization of the project costs.

- Follow-up & technical support, review and approval of the workshop drawings.

- Plans and procedures approval of supervision and health safety (HSE).

- Equipment accessibility, reception, installation & commissioning.

- Supervision and approval of onsite contractors & suppliers drawings for execution.

- Engineering tests, “Troubleshooting“ & setting of the PLC processes.

- Management and control of work quality and equipment performances.

- Onsite works progress reports follow-up, benchmark and end of the work certificate delivery.

- Update and approval of all the facility, cleanrooms and equipment drawings and documentations “As Built“.

- Certificate of Conformity, release of payments, customer facility and documentation “hand-over”.

- Sites HACCP, ISO-22000, SQF, GFSI compliance certification. PBE Expert is a MAPAQ qualified Consultant to “ La mesure 2 du programme Levier ”.

- HACCP, ISO-22000, SQF, GFSI compliance audit and pre-approval inspection (PAI).

- Development of PAI plan and procedure: before, during and after inspection.

- Corrective and Preventive Measures: CPM, RAPA, GAPA.

- Plans for remediation.

- Management and Implementation of a change control system.

- Continuous Improvement & Quality Audit of supplier’s qualification.

- Development of the Site Master File (SMF).

- cGMP Training: PBE Expert Inc is a CPMT training company with agreement #0059104 & EPIC/OIQ recognition.

- Qualification DQ, IQ, OQ: equipment & classified cleanrooms, quality control Labs equipment, freezer & cold rooms, autoclave, freeze-dryer, isolator, oven, stability room, CIP, SIP, HVAC, PW, EPPI, pure steam, compressed air, N2.

- Sampling Plan, and MACO.

- Process Validation, of cleaning and sterilization (FDA 2011, EMA 2015).

- Sterilization cycles development, Media-Fill tests.

- Computer validation, CSV: BMS, PLC, qualification of ERP software, SAP (GAMP, CFR21-11), data integrity.

- Predictive maintenance, systemic, and preventive plan & program

- Metrology, calibration program, calibration of the instruments, and traceability.

- Mapping (temperature, humidity) cold room, warehouse, freezer, incubator, autoclave, freeze dryer, microwave (thawing of foods before processing).

- Commissioning (DQ, FAT, SAT).

- Quality Assurance & In Process Control.

- Drafting of procedures: SOP.

- Manufacturing operation support and health & safety services.

- Change Control, CAPA, Failure Modes Effect Analysis : FMEA.

- Root Causes Analysis “RCA“.

- Risks management, analysis, and mitigation. Gap analysis and impact study RAPA/GAPA FMEA: ICH Q9, ATEX(8).

- Industry 4.0, IoT, collection and data integrity, CSV, ERP, SAP, LIMS.

- Training: PBE Expert Inc is a CPMT training company with agreement #0059104 & EPIC/OIQ recognition.

Regulations

BPF | FDA | ANSM | Santé Canada | GCC | ISO14644 | ASME-BPE | ISPE | ICH Q9 | AMDEC | ATEX | NFPA | HSE | SIMDUT